ProMat 2023: Touch the Future

Walking into the McCormick building, the halls were buzzing with anticipation of the ProMat 2023 show. Seeing the signage and theming come alive helped set the tone for what we were about to experience. After a 4 year hiatus (due to Covid), the manufacturing and supply chain industry came together in a big way to “Touch the Future”. On the show floor and in the theatre sessions, there was a big focus on digital supply chain solutions such as automation, robotics, artificial intelligence, autonomous vehicles, augmented reality, the Internet of Things, and end-to-end data transparency. During the show, we learned how these new technologies work seamlessly with traditional material handling solutions to make efficient end-to-end operations possible.

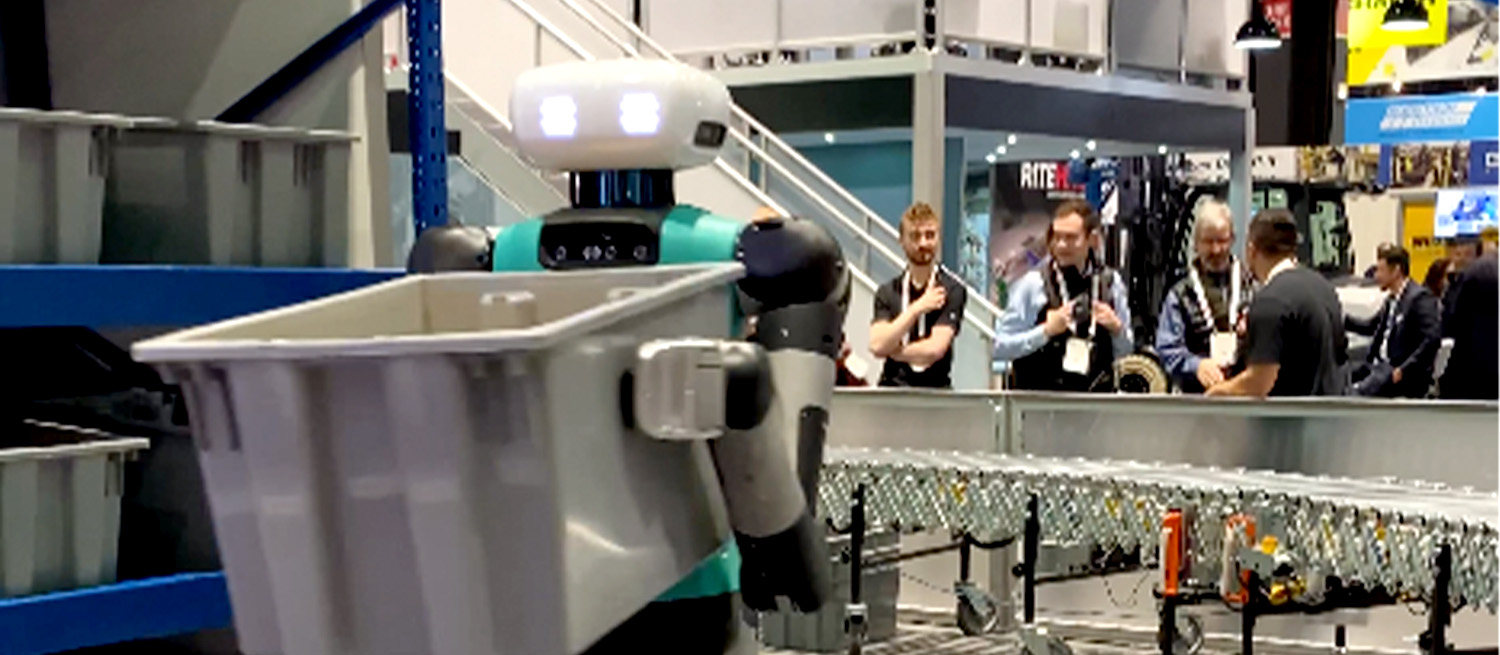

One topic that piqued my interest was human-centric robotics. I was curious as to how these machines will be integrated into different industries and the overall impact they will have on the workforce. During the Session “Human-centric Robotics: Walking into the Warehouse” presented by Jonathan Hurst with Agility Robotics, We learned about Digit, the multi-purpose, human-centric robot that can move totes in warehouses between shelves, conveyors, and cards. Jonathan shared how robotics and automation are critical to the future of logistics and increasing human productivity in general. While one may worry about how this integration may take away many jobs, studies show that there has been a shift in the workforce over the past 3 years which has created a large gap between the number of job openings (10.7M) and unemployed workers (5.7M). So there is a big opportunity for learning/training people in new roles which sounds promising.

To close out the session, Jonathan shared his prediction on the path forward for how human-centric robots will become commonplace in warehouses, other industries, businesses, and then homes eventually:

ERA 1: Proof of Concept

A few Multi-purpose robots can do a single job well.

Ex: A fixed robotic arm and other forms of mechanical automation

ERA 2: Proof of Scale

Many robots d a single job.

Ex: Autonomous mobile robots, operating in warehouses and spaces designed for automation. But with some mobility enabling tasks beyond fixed systems.

ERA 3: Multi-purpose

Many robots do many different jobs (a new revolution of Robotics).

Ex: Human-centric robots designed to go and operate near and around us

ERA 4: Robots as a Platform

Businesses deploy multi-purpose robots for their jobs and tasks

ERA 5: Robots as Common helpers

Consumers ask robots to do tasks that they need help with.

After the session, we headed back to the show floor to meet Digit at the Agility Robotics booth to see its capabilities in action!